Should you repair or replace your induction coil? Let eldec’s experts inspect your coil and recommend a course of action.

Inductors are expensive, so if you are able to have your induction heating coils repaired, you can save some money. But how do you decide whether to repair or replace an inductor?

eldec’s repair technicians say it really depends on the evaluation of the individual coil in the repair shop. Sometimes the cost of repair is so high that it makes more sense financially to replace the coil.

Other coils – those that need a little straightening or have a small leak in a braze joint – can be repaired fairly inexpensively. When in doubt, coils can be sent in for evaluation by eldec’s skilled team. From there, coils can either be repaired, returned or scrapped out based on customer's preference.

Table of Contents:

- The most common issues with inductors

- Top quality induction coil repair and refurbishment services

- The process of repairing induction heating coils

- Repairing all shape, size and brand coils

- Induction coil maintenance to avoid repairs

The most common issues with inductors

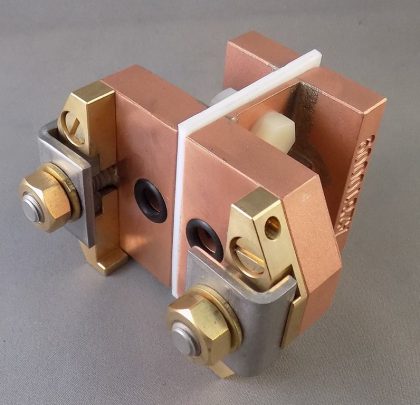

An example of an induction coil damaged beyond repair.

Human error is usually to blame when inductors are damaged. They are often dropped, knocked off of work benches or not cleaned or stored properly.

The photo on the right is an example of a coil that should be replaced. It is leaking in two or three places on the circular head. The cost of time and materials to fix this coil makes it a candidate for a complete replacement. The following list includes the most common issues our technicians see with damaged inductors.

- Bent or broken coils

- Electrical shorts

- Damaged leads

- Build-up of foreign materials

- Damage caused by improperly installation

- Damage caused by using dirty water

Documenting good housekeeping and safety rules for employee training can help prevent many of these problems.

Top quality induction coil repair and refurbishment services

Repairing inductors is a manual process that requires painstaking proficiency. Our skilled technicians are highly trained and have inspected, repaired and refurbished coils in Michigan for more than 20 years. They have a thorough understanding of many induction heating applications, and over the years, have witnessed many types of damage. This level of experience and expertise allows them to troubleshoot, repair induction coils and return them quickly. Turn around for emergency repairs can be as fast as two to three days after receipt of order depending on the type of repair needed. Same day refurbishment is possible depending on the location of your plant and the willingness of your courier to wait while we repair the coil. Call us rather than email if you have an emergency.

Repairing inductors is a manual process that requires painstaking proficiency. Our skilled technicians are highly trained and have inspected, repaired and refurbished coils in Michigan for more than 20 years. They have a thorough understanding of many induction heating applications, and over the years, have witnessed many types of damage. This level of experience and expertise allows them to troubleshoot, repair induction coils and return them quickly. Turn around for emergency repairs can be as fast as two to three days after receipt of order depending on the type of repair needed. Same day refurbishment is possible depending on the location of your plant and the willingness of your courier to wait while we repair the coil. Call us rather than email if you have an emergency.

Induction coil repair and redesign services include:

- Inspection and testing

- Repair and refurbishment

- Replacement using the current design

- Application process review and redesign of the damaged inductor

- Emergency repairs

The process of repairing induction heating coils

The induction coil repair process begins when damaged coils are shipped to our facility and then are inspected prior to repair. To reduce downtime, once an inspection report is reviewed and the refurbishment is approved, eldec moves quickly to complete the repair, re-inspect, test and return the inductor to your facility. If our technicians spot a recurring issue with damaged inductors at a facility, they will offer suggestions on how to avoid similar damage to coils in the future. If you decide it is more cost efficient to replace the coil rather than repair it, we can build a new coil based on the old design. Typically, we do prototype runs to demonstrate our expertise and meet our customers’ expectations.

Repairing all shape, size and brand coils

Accidents happen. When they do or even if your coils simply wear out, give eldec a call. We can shorten costly down time at your plant by repairing or replacing your coils quickly – all shapes, sizes and brands of coils – whether we made them or if they were manufactured by one of our competitors. Our commitment to quality and a quick turnaround for induction coil repair will have your operation back up and running smoothly.

Inductor repair and refurbishment at a reasonable price

Induction coil repair prices vary by the extent of damage as well as the size and type of the coil. Less seriously damaged coils can be repaired relatively inexpensively. In other cases, it may be more cost effective to replace the coil. Our technicians will do a thorough inspection and recommend the best course of action. Deciding between repairing or replacing the coil is then left up to you.

Induction coil maintenance to avoid repairs

Coax Saver by eldec LLC

Use and abuse are often the culprits to blame for damaged induction heating coils. Coils get dropped, banged up and dirty. According to Mark Kozlowski, eldec LLC’s Service Manager, a little TLC and induction coil maintenance can go a long way to helping extend the life of this expensive type of tooling.

- Protect your inductors. They can be fragile. Put them away when not in use. Don’t leave them near the edge of a workspace where they could be knocked off or dropped. This is especially true for coils that are used in hand-held operations, such as brazing copper. Dropped coils not only might break, but they could also stop functioning or lose their form.

- Use clean water for your operation. Heating with a low water flow or dirty water will shorten the life span of the coil.

- Clean your coils after use. Build-up of foreign materials can cause a short across the leads and damage the coil. The best way to clean a coil is to wipe the coil off with a clean towel or rag and blow the particles off with compressed air. A Scotch-Brite™ pad can be used to clean the coil foot electrical connection point.

- Inspect the Teflon® insulator between the copper leads for damage prior to use to avoid shorts.

- Use a coax saver, which is an adapter that acts as a short extension between the coax transformer and the induction coil. If this type of adapter is used and the coil is mistakenly installed too loosely or too tightly, the damage occurs to the coax saver (which is relatively inexpensive) rather than the expensive coil or coax transformer.

- Install your coils properly. Installing induction coils correctly can prevent costly down time and repairs.

Follow these tips to avoid repairs and your inductors will last longer.

Induction heating coil repair and maintenance experts saving you time and money

eldec is proud of its reputation as a top notch, induction heating coil repair company. Our technicians pursue perfection like artists and have the specialized expertise and experience to know how inductors work best. We also know that short lead times and on time delivery are critical to your operation. Our current backlog is well positioned to allow a quick turnaround when you’re in a pinch. Give us a call or send us a request and we’ll contact you. Need a completely new inductor designed? We do that well, too. Read more about our custom inductor design and fabrication capabilities. We also offer process development services for customer-specific applications such as: brazing, shrink fitting, annealing and pre-heating for welding.